TL120 Compact Wheel Loader

The Schaeff TL120 wheel loader comes with a powerful hydraulic system offering hydrostatic drive technology. That gives you smooth power development with no loss of traction. There’s articulated steering for superb manoeuvrability and an oscillating rear axle that keeps all four wheels on the ground at all times. And our parallel kinematics system allows you to lift a load quickly and precisely without constantly having to adjust the loading angle.

POWERFUL HYDRAULICS

Hydrostatic high-pressure transmission helps maximise productivity, thanks to the hydrostatic drive technology we employ that delivers smooth power development without any interruption of traction. In addition, the third-section hydraulics work completely independently of the hydraulics for transmission and can be used to operate the hydraulic quick coupler and common work tools. Use the additional control circuit (fourth section) for operation of special attachments which require hydraulic oil flow. The fourth section is also available with an optional high flow function.

ARTICULATED STEERING

Reliable, stable, and highly, highly manoeuvrable. That’s the articulated steering function on the TL120, with its 40° steering angle. Even if your steering is at full lock, the bucket will still approach loads head on. So it’s perfect for picking up or setting down pallets in tight spaces. You’ll also enjoy stability in the wheelbase, with all four wheels pointing in the same direction to protect lawns and pavements. And you’ll save on tyre wear with the short turning circle.

OSCILLATING REAR AXLE

We never forget our obligations towards our operators, particularly around health and safety. That’s why all four wheels of the TL120 remain in constant contact with even the toughest ground. That’s down to the oscillating rear axle’s wide slewing angle of 10 degrees. With some manufacturers, the whole back end oscillates. This is destabilising as the bucket and the machine are moving in different directions. With just our rear axle oscillating, we get around this problem.

PARALLEL KINEMATICS

Wouldn’t it be great to be able to concentrate only on setting down your load precisely where you want it? Not having to worry about constantly adjusting the loading angle when lifting loads? Parallel kinematics is the answer. Our system takes care of the stroke angle, allowing you to set down your load with precision. Parallel kinematics can also optimise work cycles when loading and unloading the second row on a truck, stopping the tilt-control lever from hitting the body of the truck.

SMART CONTROL

Once you’ve set up individual drivers in our Smart Control system, their settings get committed to memory. So operators start work quickly, using settings they’re most comfortable with. It’s simple to use, too. If you can use a smartphone‘s tiled interface, you can use Smart Control. On the 3.5-inch display, you can clearly read machinery and engine data, while the windscreen domes inwards to minimise the mirror effect. There’s a keypad with extra-large keys for further ease of use.

OPERATOR STATION

At Schaeff, our machines are designed with user-experience in mind, so we offer driver comfort that makes for greater productivity. We built the cabin of the TL120 with noise and vibration damping and ensured it’s ROPS/FOPS-approved. We want you to stay safe on site, so we provide large windows, and a door on each side of the cabin offers both ventilation and better communication with colleagues. There’s even adjustable hydraulic suspension on the operator’s seat for a smooth ride.

TRAVEL SPEED

There’s plenty of power available in the TL120, but that’s not at the expense of fuel consumption. It’s a balancing act that we’ve pulled off well thanks to our hydrostatic travel drive. And on the road? You can expect to reach 20 km/h en route to the next job site, but if you need more power, you might consider our high-speed version, with a top speed of 36 km/h.

BRAKE INCHING PEDAL

To improve the cycle time of digging and loading operations, you’ll need to slow the loader while keeping the engine rpm up. You can do this with our brake inching pedal, which fine-tunes the hydraulic performance. The brake inching pedal also avoids excessive tyre wear and wheel spin.

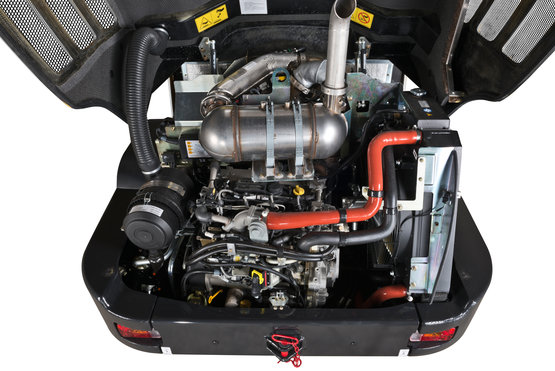

EASY MAINTENANCE

Open the engine hood and there’s plenty of clutter-free room to get to all the key components, including engine oil, water and filters. This makes daily maintenance easy and fast. This will help reduce the total cost of ownership of the machine. And being able to perform routine tasks from ground level saves time and contributes to safety.

SMARTASSIST REMOTE

SmartAssist Remote is Schaeff’s next-generation fleet-management system. It remotely monitors your machinery over the internet, rapidly detecting issues and notifying us of maintenance timings. So you get the quality support and service you need to maximise productivity. You get real-time information and the ability to monitor and manage machines remotely over a PC or smartphone.

OPTIONS

EQUIPMENTS

- Diesel engine with DPF

- Fan drive, controllable and reversible

- Front and rear axle 36 kph incl. plate light

- Extended lifting frame – dumping height + 640 mm at bucket hinge pin height

- 4th control circuit, electro-proportional control and installation on lift frame incl. couplings and continuous operation

- Hydraulic installation, hydraulic quick-attach system with two-hand operation

- Biodegradable hydraulic oil / ester-based HLP 68 (Panolin)

- Provision of hydraulic oil (oil approval by Yanmar required)

- Low-temperature package fluids

- Battery (12 V / 135 AH)

- Throttle, adjustable, for lift or tilt cylinders

- Open return, on lift frame

- Hydraulic outlet for front hand-held hammer, with flow divider

- Ride control system LSD

- Semi-automatic bucket return positioner incl. lift height limitation

- Couplings, 3rd control circuit (Flat-Star)

- LED working floodlight, rear (2 pieces)

- Rotating beacon, yellow

- LED Rotating beacon, yellow

- Manual throttle, with transmission deactivated

- Crawling speed, without electronic control

- Reversing camera, color monitor

- Retrofit kit for road homologation Italy, lifting frame support, license plate light (double row), beacon (yellow), wiring harness (Option1)

- Option package Premium

COMFORT

- Sliding window on right-hand side

- Option package Comfort

- MSG 85 comfort seat

- MSG 95 Premium seat

- MP3 Radio

- Headrest suitable for comfort and premium version

- Air-conditioning, cpl.

- Arm rest, left, for driver’s seat

- Outside rear-view mirror, heatable

- Engine-independent diesel heater with timer

- FOPS retrofit kit (skylight guard) with CE certificate

- Seat belt lock with safety device

- Lap belt, 76 mm wide

- Pollen filter

- Additional cab insulation and heating

- Sun-blind, front windshield

- Central lubrication system (Lincoln)

SAFETY

- Lifting certificate

- Option package Safety

- Back-up alarm for reverse travel

- Lift frame support, for transport position and lock (Italy)

- Fire extinguisher, ABC powder, 2 kg, mounted in the cab

- First aid box

- Fork rake support

- Safety valves for lift and tilt cylinders

- License plate illumination (for 20 kph)

- Load warning device, visual and acoustic

- Safety decals, StVZO, red/white

- Warning decals “road travel”

- Jump-start connection point

- Anti-theft device, coded key

- Immobilizer, electronic, keypad operation

- Automatic Engine Shutdown

- Electrical refueling pump, cpl. with mounting kit

- Warning triangle

- Activated charcoal filter

- Turbo II prefilter

- “TÜV” approval (Germany)

- Provision of general operating license

- Special tires

- Special paint